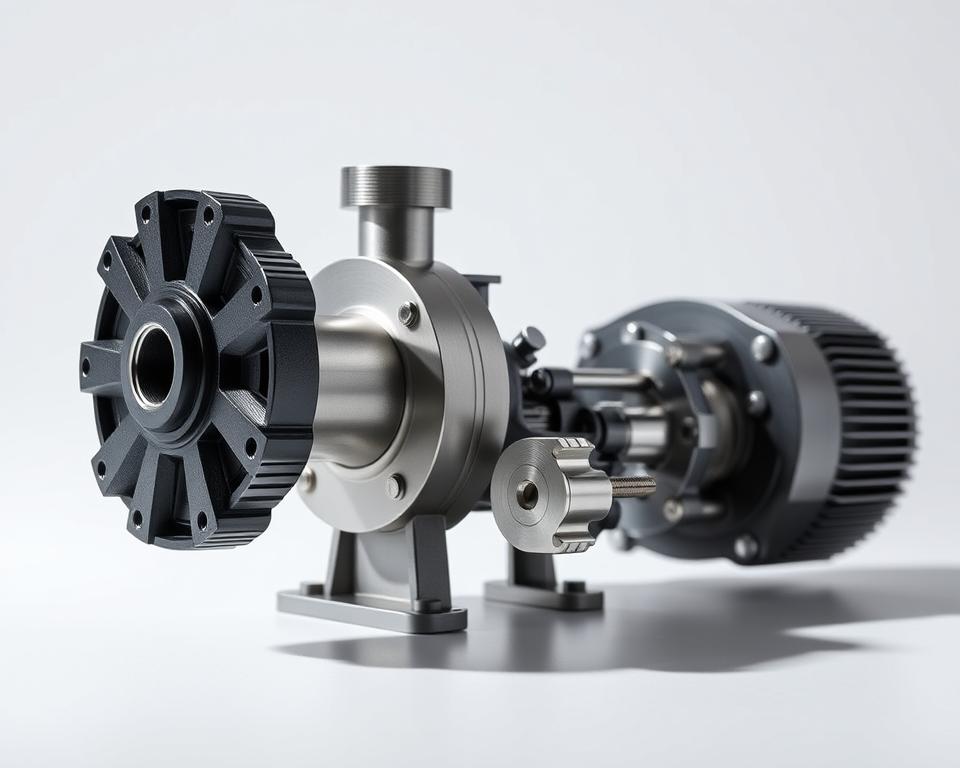

Shurflo Pump Parts – Essential Elements Guide

Did you learn that Shurflo’s 2088 and 8000 Series Pumps include over 101 unique models? Each one incorporates dedicated parts like the Switch Assembly and Check Valve Assembly. This exhibits the vast selection of Shurflo pump parts, highlighting the need for original components for peak output.

For individuals in agricultural production, food and beverage, or HVAC, selecting the right Shurflo water pump diagram proves essential for effectiveness. This guide examines the crucial components that ensure Shurflo Pump operate effectively. It seeks to enable you to purchase Shurflo components with certainty.

Critical Points

- Shurflo provides over 101 individual versions in its 2088 and 8000 Series.

- Every version features particular components critical to pump functionality.

- Genuine Shurflo Pump Components are key in maintaining optimal performance.

- Component availability differs, with some parts noted as available when asked.

- Knowing component compatibility is key when buying spare parts.

Introduction to Shurflo Pump

Shurflo Pump are essential in many industries, aiding in fluid transfer. The correct model boosts efficiency and performance in operations. Known for a varied lineup, the brand meets multiple operational needs.

Overview of Shurflo Pump Models

Shurflo offers versions like the 5000 and 2088 series. The 5000 series is designed for long-lasting performance and chemical resistance, ideal for harsh environments. The 2088 series excels in high-flow, medium-pressure applications such as misting and fertilizing. Understanding these versions assists in selecting the correct Pump for specific needs.

Applications of Shurflo Pump

Shurflo Pump are versatile, used in agriculture for application, watering, in RVs for liquid, and in boats for bilge extraction. Understanding these uses guarantees their best use and longevity. Having access to spare components is critical for pump maintenance.

Grasping Shurflo Pump Parts

To maximize your Shurflo pump’s efficiency, understanding its components is vital. Each element significantly affects performance and longevity. Being familiar with these components aids in effective upkeep and repair.

Essential Components of Shurflo Pumps

Shurflo Pump are built with several critical components. These enhance the operation of the pump:

- Diaphragm: Crucial for creating force to move fluids.

- Motor: Drives the pump, necessary for liquid transfer.

- Pump Head: Contains the diaphragm along with its inner components, crucial for the pump structure.

- Pressure Switch: Maintains the pressure in check, ensuring safe operation.

Why Authentic Shurflo Components Matter

It’s critical to employ authentic Shurflo components for replacements. Low-quality components can lead to numerous issues:

- Reduced performance and operation.

- Higher risk of pump failure.

- Possible hazards due to malfunctioning components.

Employing genuine Shurflo components offers advantages such as better durability and proper fit. This ensures a prolonged life and consistent operation of your pump.

In-Depth Look at Shurflo Components

Grasping the intricate composition of Shurflo Pump is crucial for their seamless functioning and upkeep. Regular care of these elements guarantees their optimal output and prolonged durability. We’ll dive into the crucial parts such as the Pump Head, diaphragm, and electrical pieces, emphasizing the importance of premium Shurflo repair and maintenance parts.

Pump Head and Valves

The Pump Head is pivotal by housing vital valve assemblies that manage the liquid flow and pressure of fluids. To avert leakage and ensure optimal operation, these valves need frequent checks. Maintaining the pump head in top shape wards off inefficiencies and enhances the pump’s durability. Employing high-quality Shurflo replacement components for valve replacements guarantees smooth operations.

Diaphragm & Motor Details

The diaphragm, constructed using strong materials like Santoprene or Viton, is crucial to the pump’s effectiveness. These substances offer excellent chemical resistance and last a long time, ideal for various uses. Different models have variations, with motor details significantly affecting efficiency. Regular inspections of these components indicate when Shurflo maintenance parts are necessary for reliable operation.

Pressure Switch and Electrical Components

The Pressure Switch’s role is to stop the Motor upon reaching the configured pressure, safeguarding it due to lack of flow. Standard settings usually maintain the discharge pressure about 15-20 psi under the shut-off level. Maintaining electrical components in prime condition is essential for both security and performance. Regular inspections confirm all Shurflo replacement components are matching and operational.

| Component | Specifications | Importance |

|---|---|---|

| Pump Head | Encloses valves and regulates flow | Prevents leaks; ensures efficient flow |

| Diaphragm | Constructed from Santoprene and Viton | Ensures longevity and chemical resistance |

| Pressure Switch | Standard pressure setting: 15-20 psi | Prevents deadheading; protects motor |

| Motor | Specifications vary, impacting performance | Critical for pump operation; energy consumption |

Buying Shurflo Spare Parts Online

It’s crucial to select the right vendor for Shurflo pump parts to ensure optimal operation. Reputable suppliers ensure you get authentic Shurflo parts online, simplifying the maintenance process. Confirming the compatibility of the components with your pump model is critical to avoid installation or performance issues.

Sources for Authentic Shurflo Spare Parts

Installation Parts Supply is a dependable source for genuine Shurflo parts online, providing 114 varieties. They carry components for multiple applications, including motor voltage like 12V, 115V, and 24VDC. Their inventory features pressure regulators, strainers, valve assemblies, and diaphragm kits. Be sure to check these options to ensure you choose the best parts for your pump’s performance.

Verifying Component Fit with Your Pump Model

Verifying the fit of Shurflo pump parts before purchase is crucial. Users should refer to product details and instruction guides to guarantee compatibility. With a broad selection of pressure regulators, strainers, and diaphragm assemblies, locating the correct component is simpler. Understanding your Pump’s requirements prevents issues from mismatched parts.

Shurflo Pump Maintenance Parts

Routine upkeep of Shurflo Pump guarantees they perform optimally for extended periods. This reduces the risk of unexpected failures and expensive fixes. It’s crucial to inspect critical components like the motor and diaphragm to keep the pump working well. For effective upkeep, keep an eye on the pressure switch and look for indications of degradation in other parts.

Recommended Maintenance Practices

- Examine motor functions regularly to avoid excessive heat buildup.

- Check the pressure switch for stable readings.

- Ensure the diaphragm’s condition to prevent leaks.

- Clean filters and valves to maintain proper water flow.

- Lubricate moving parts as needed to ensure smooth operation.

Common Shurflo Pump Repair Parts

Having the right replacement components is critical for upkeep or fixing issues. Commonly needed components consist of:

- Pressure Switches

- Diaphragm

- Valve assemblies

- Motors

- Seals and gaskets

Having these parts on hand allows users to quickly solve problems. This enhances the dependability and efficiency of their Shurflo Pump setups.

The Bottom Line

Grasping Shurflo Pump Parts’ composition and functionality is essential for their effective use and maintenance. Using genuine replacement parts ensures efficient and safe operation, minimizing downtime and expensive repairs. Routine upkeep, like inspecting and swapping out key parts including the Diaphragm and Pressure Switch, increases your pump’s lifespan.

Installation Parts Supply is a trusted vendor for high-quality Shurflo pump parts. This access to necessary components and supplies guarantees that Shurflo pumps deliver peak efficiency. Such maintenance is vital for various applications, from boat to agricultural settings.

Maintaining voltage within ±10% of the specified rating and installing correctly can extend a Shurflo pump’s lifespan to as much as eight years. Taking preventive measures and using genuine parts is crucial for achieving optimal performance.

FAQ

Which Shurflo pump parts can be found?

Shurflo offers a wide range of pump parts. These comprise genuine replacement parts, multiple add-ons, and upkeep essentials like Diaphragm, Motor, and Pressure Switches.

Which websites offer genuine Shurflo pump parts online?

Genuine Shurflo pump parts are sold online through trusted suppliers such as Installation Parts Supply. Buying from reliable vendors ensures you get real components for your pump.

How do I know which Shurflo pump parts are compatible with my model?

Verify by reviewing your pump’s product specifications and manuals. This guarantees you choose the appropriate components for your particular Shurflo pump model.

Why is it important to use genuine Shurflo replacement parts?

Using genuine Shurflo components is essential for your pump’s efficiency and safety. Poor-quality parts may result in failures, decreased performance, and safety risks.

What are some common maintenance parts for Shurflo pumps?

Key maintenance parts include Diaphragm, Pressure Switches, and valves. Routine inspections and substitutions of these items maintain your pump remains in top working condition.

How long does a Shurflo pump typically last?

Its lifespan varies based on usage and maintenance. With proper maintenance, these pumps can operate for years. Authentic components are key to extending their operational life.

Can I perform repairs on my Shurflo pump myself?

Yes, if you have some technical knowledge, you can handle many repairs. It’s crucial to use genuine parts and adhere to the manual’s directions for safety and efficiency.